Indicator bolts

Indicator bolts are quite new products; however, thanks to their innovative features they are becoming increasingly well-known within the field of high-pressure applications.

INDICATOR BOLTS

The function of the Indicator Studbolt is to evidence at all times the dynamic stresses that it undergoes and if these stresses are within the limits of the design of the system.

The values that are verified are the length variations of the torque element; this variation is a direct relation of the following two parameters:

-Temperature

-Pressure

To satisfy these requirements the Indicator Studbolt must be constructed as follows:

-

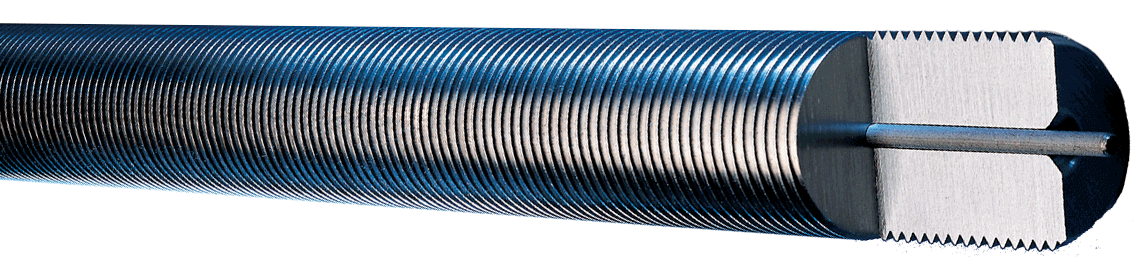

Axial drilling of the studbolt for all its length.

-

Counterboring of one of the two ends of the studbolt to allow for welding of the indicator rod that is the instrument of comparison of the variations in dynamic stress.

-

Thread rolling.

-

Degreasing of the rolled studbolt to eliminate ali residues that could damage the integrity of the weld.

-

Insertion of the indicator rod that must run smoothly within the drilled bore of the studbolt.

-

Welding of the indicator rod to the studbolt at the counter-bored end. Depending on the requirements of the customer, welding operations may be effected in TIG or with a specially coated electrode.

-

Finish-grinding of the end opposite to that which is welded to ensure that the ends of the studbolt and of the indicator rod are placed on the same plain and are orthogonal to the axis.

Indicator studbolts can be made in low-alloy, austenitic, ferritic steels, duplex and superduplex grades, in relation to the ambient conditions.

Where possible the indicator rods should be of the same material as the studbolt to ensure that there are no elements that may mislead even in a minor way the monitored data after installation; by minor one intends the fact that the expansion coefficent defined as "K" is an extremely small element , in the region of the 6th decimai point. For chemical-physical reasons for low-alloy steel studbolts it is best to use for the indicator rods materials such as Alloy C-276 whose K coefficent is similar if not the same to that of the material used for the studbolt.

The drilling process is one of the decisive factors in the execution of the indicator studbolt.

The axiality of the bore is maintained with tolerances close to + / -zero and bore diameters as small as 1/8".