The quality of the manufacturing process

Bea’s manufacturing process is built on a solid foundation, ensuring quality at every stage—from raw materials to the finished product. Every aspect of production is handled in-house, made possible by Bea’s agile and streamlined corporate structure. This agility not only makes Bea a significant player in the market but also enables a rapid response to customer needs. Today, Bea stands out as one of the few companies in the fastening components industry that can offer the level of flexibility demanded by the market. This capability is invaluable.

Key Stages of the Manufacturing Process

At Bea, our manufacturing process is meticulously organized into several key stages, each crucial for ensuring the highest quality of our fastening components. From the initial cutting of raw materials to the final shipping of finished products, every phase is carried out with precision and care. Below is an overview of each stage of our comprehensive process.

Cutting Department

Thread Rolling Department

Forging Department

Chamfering and Marking Department

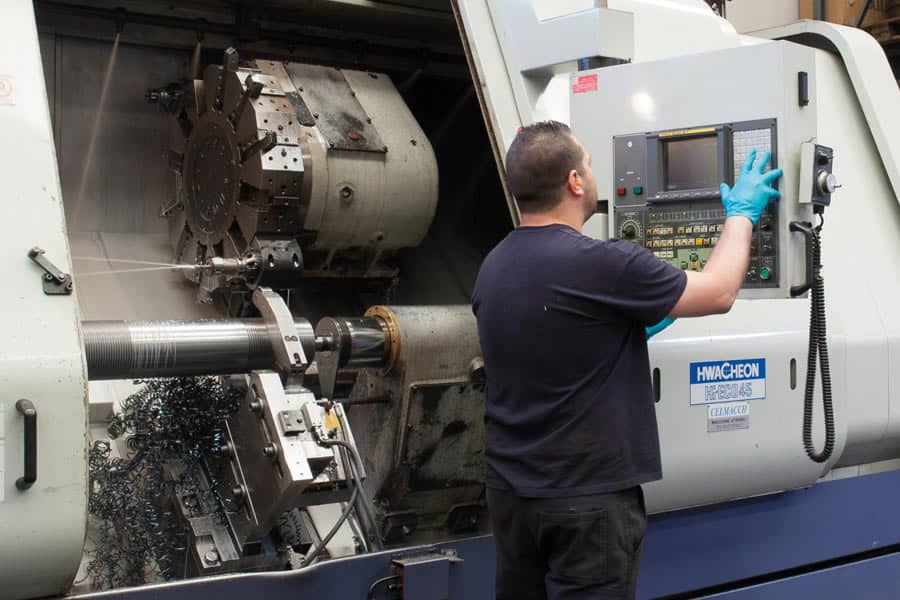

Machining Department

Thread Tapping Department

Our Laboratory

Bea’s laboratory is equipped with appliances that are dedicated to control of incoming raw materials, in-process controls for material in production and final control once production is finished. Raw material comes from approved steel mills who undergo regular auditing and their supplies are subject to all controls by the standards in force. In addition, upon demand of the customer, Bea is available to perform in-house inspections on the materials in the presence of external bodies, such as Lloyds Register, Bureau Veritas and TUV or inspectors nominated by the same customer.

DESTRUCTIVE TESTING

- Tensile Test

- Proof Load Test

- Hardness Test (Brinell - Rockwell C - Rockwell B)

- Impact Test (From room Temperature to -196°C)

NOT DESTRUCTIVE TESTING

- Ultrasonic Test

- Magnetic Particle Inspection

- Liquid Penetrant Examination

- Positive Material Identification

Heat treatments

Hot forging and production of highly specialized material grades led Bea to internally develop the heat treatment technology for the highest steel grades, alloys and non-ferrous alloys, which is performed by means of five furnaces that may reach temperatures up to 1180°. The in-house performance of this operation offers clear advantages to the customers concerning an increased control over the entire manufacturing process.

Bea carries out the following heat treatments totally in house: Quenching and tempering, Solution heat treatment, Normalizing, Age hardening and Tempering.

All furnaces at BEA are electric type, controlled atmosphere (nitrogen or nitrogen-methanol).

By conducting these processes internally, we maintain exceptional control over the entire manufacturing process, ensuring superior quality and consistency for our customers.

This comprehensive approach guarantees that every fastener we produce meets the highest performance and durability standards.

Comprehensive range of surface treatments (coating)

Bea can perform any type of surface treatment upon demand of the customer by complying with the provisions that are established by the reference standards.